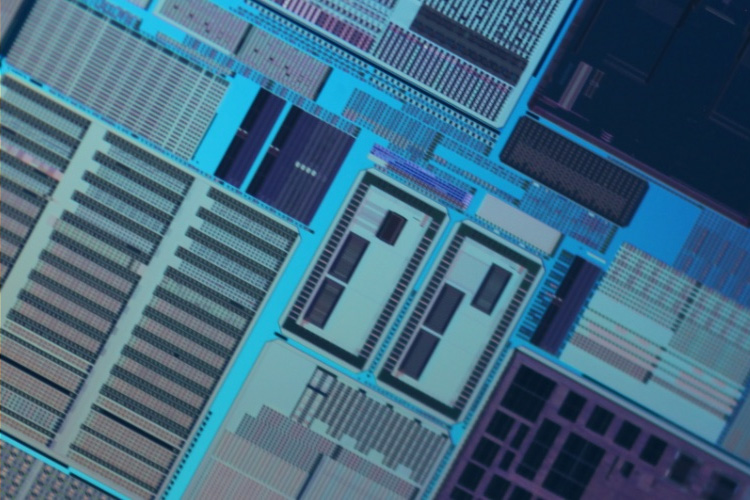

USJC provides Contract manufactuaring servise of Semiconductor as a member of UMC in Taiwan (the world's third largest foundry).

We have one of the largest 12 inch Logic LSI plant in Japan and produce 38,400 wafers/month.

We implements proactive disaster mitigation measures, including the installation of earthquake-resistant structures, establishment of Li-capacity backup power supply, and deployment of LNG satellite bases.

USJC Strengths

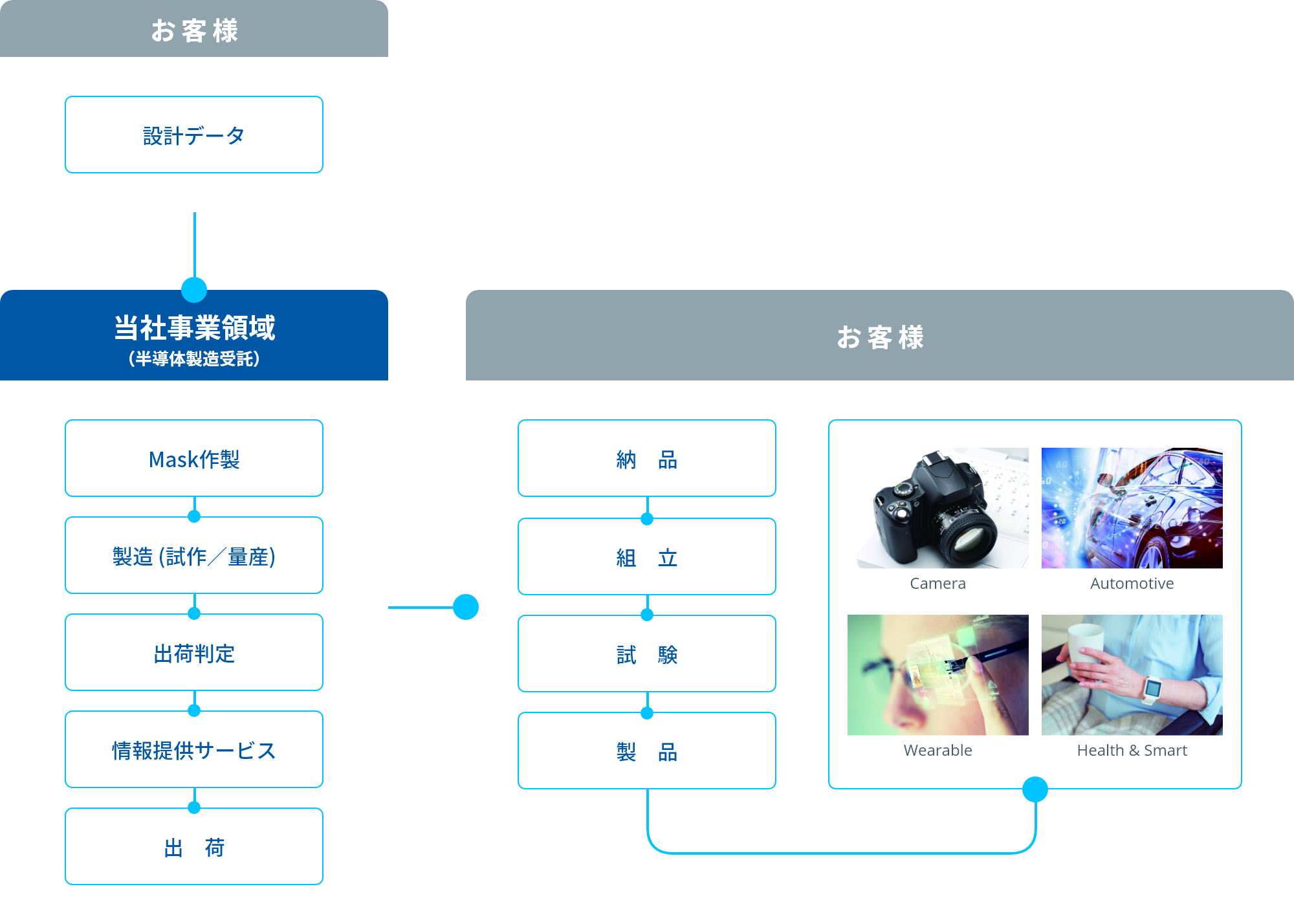

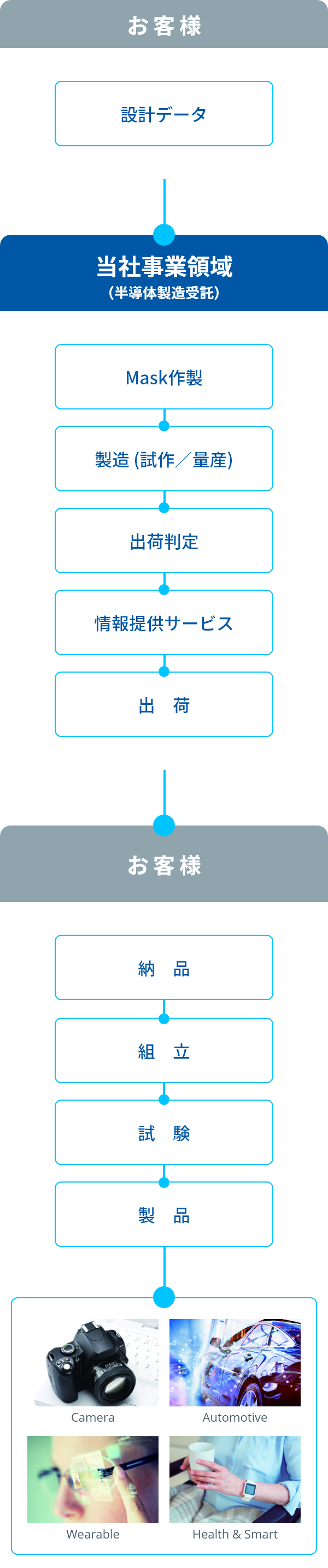

Business Area

-

Foundry Service

USJC offers a range of services that cover everything from design support to manufacturing. Our customers benefit from our extensive 40 years of experiences, allowing us to provide speedy and efficient solutions to meet their needs.

Learn More

-

MyUSJC

Our foundry information service, MyUSJC, provides customers with access to our design technology offerings, customer product information, and measurement results.

Learn More

-

Shuttle Service

The shuttle service is a prototype service using a Multi Project Wafer (MPW). By allowing several customers to share masks and wafers, chip prototyping can be completed at a reduced cost.

Learn More

-

Technology

Together with our customers, USJC aims to contribute towards the realization of a smart society through the technologies and services we provide. Our advanced technology and support allow us to produce products that support the development of a smarter society.

Learn More

-

Mie Plant

Surrounded by an abundance of water and rich natural environment, the Mie Plant aims to be an advanced semiconductor manufacturing fab that maintains harmony with the natural environment.

Mie Plant certified to Environment Management System(EMS) "ISO14001"Learn More

-

Domestic Sales

USJC sales team is available to assist customers in Japan with accessing UMC Group's fab capacities and technology.

Learn More

USJC History

Mie Plant has played a crucial role in the expansion of Japan's semiconductor industry since its establishment in 1984 as a platform for developing prototypes and manufacturing logic, bipolar, and memory products.

Here is a brief overview of its advancement.

History of Mie Plant

~ From the Birth of Semiconductor to the Present ~

1984

Establishement of Mie Plant

In October, Mie plant was established and started operation of Fab-1 (150㎜) for prototypes and mass production of large scale memory and large gate-array

1985

First shipment of EPROM Products

1988

In September, Fab-2 (150㎜) started operation

1991

In July, Fab-3 (200㎜) started operation.

1992

Establishment of the world's first mass production fab for GaAs IC in Japan Development of the world's first CMOS based vector processing LSI (Super computer's operation function is in one chip)

1995

Mie Plant was certified to ISO9001 (1994 Version)

1996

Mie Plant was certified to ISO14001 (1996 Version)

1998

Fab-2 changed to 200㎜ from 150㎜

2003

Started mass production of 90㎚ Cu multilayer wiring

2004

Completion of new 300㎜ wafer manufacturing fab (Fab-B1) at Mie Plant

FPGA's foundry agreement with Lattice Semiconductor (U.S.)

2005

Fab-B1 started production of 90㎚ products in April

In September, initial introduction of NAS battery

2006

Establishment of 2nd 300㎜ manufacturing fab (Fab-B2)

In September, concluded a license agreement with MoSys Inc. to use “IT-SRAM®”, an embedded memory technology, based on 65㎚ process

2007

Fab-B2 started production of 65㎚ products

Success in generating and recovering high purity stone from concentrated hydrofluoric acid wastewater

2008

Spin-off of Fujitsu Limited Semiconductor Business Unit as Fujitsu Microelectronics Limited

In August, ISO/TS16949 was certified

2009

The headquarter of MIFS relocated to Shin-Yokohama Central Building (JR Station Building)

2010

Change of the company name to Fujitsu Semiconductor Limited

Production start of LSI for Supercomputer “K”

2012

Success in breeding "killifish" bred for monitoring water discharge

2013

In April, LNG satellite base was installed in the factory

In September, mass production of DDC transistors based products started

In December, developed manufacturing technology to embed Flash memory cell in logic circuit with DDC technology

2014

In December, Mie Fujitsu Semiconductor Limited was established with capital participation by UMC (Taiwan)

Establishment of Mie Fujitsu Semiconductor Limited

2015

In April, MIFS acquired IPR (intellectual property right) of ultra low power technology from SuVolta

In November, a new clean room adopted SWIT(Swirling Induction Type HVAC system)

2016

In April, MIFS announced partnership with Kilopass in the field of technology development

In April, MIFS made an announcement of combining Deeply Depleted Channel (DDC) and near/sub-threshold technologies to reduce energy

In August, MIFS and FSL announced an agreement with US-based Nantero, Inc. to license that company's technology for NRAM, non-volatile RAM using carbon nanotubes, and to conduct joint development

MIFS was certificated ISO 9001:2015

Mie Plant was certificated IATF 16949:2016

2019

Corporate headquarter and Shin-Yokohama Design center are relocated to Yokohama

MIFS was certified to ISO14001:2015

UMC Receives Final Approval for 100% Acquisition of Mie Fujitsu Semiconductor

Establishment of United Semiconductor Japan Co., Ltd.

2020

In July, USJC was certificated ISO/ICE 27001:2013

2021

In July, USJC was certificated ISO22301:2019

2022

In April, Collaboration with DENSO to production of power semisonductor

USJC was certificated ISO45001:2018

2023

In April, USJC was certificated "ISO27001:2022"

In May, DENSO and USJC started mass production shipment of automotive IGBT

2025

In August, USJC was certificated "IECQ QC 080000:2017"