Reduce CO2 Emissions from Energy Consumption

USJC is continuing its efforts to use energy more efficiently. The production lines of USJC are energy-saving plant used the most advanced technology available when they were constructed. We also continue to promote reduction measures by planning and executing efficient energy use to contribute to global warming prevention every year.

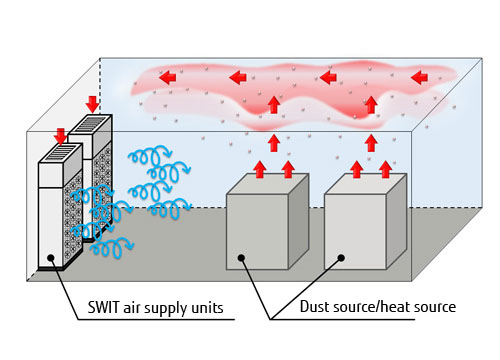

SWIT® (Swirling Induction Type HVAC system)

USJC has introduced Swirling Induction Type HVAC system (SWIT) in semiconductor manufacturing line for the first time in the world since 2015. “SWIT” is a system to create temperature strata inside the cleanroom and works with rising air currents created by heat-generating equipment to carry airborne dust toward the ceiling. We have adopted the same system for the plant expansion in 2022, striving to reduce environmental impact and manufacture high quality products.

Overview of SWIT system

Introduction of High-efficiency centrifugal chiller with new refrigerant

When USJC replaced the chiller in the plant area starting in 2020, we selected High-efficiency turbo centrifugal chiller that would help us address climate change that would be effective in both saving energy and reducing the load of refrigerant Freon as a measure to address climate change issues.

We replaced two chillers in 2023, and by 2030, we will replace all chillers in our plant with high-efficiency chillers using CFC-free refrigerants which are not subject to the revised Fluorocarbon Emissions Control Act.

We will keep working on energy conservation and global warming countermeasures.

chiller refrigerant comparision

| Existing | New | |

|---|---|---|

| Refrigerant | R-134a | R-514A |

| Pressure | High | Low |

| Classification | Freon | Non-Freon |

| GWP※ | 1430 | <2 |

※Global warming potential

Centrifugal chiller with Non-Freon refrigerant

![]()

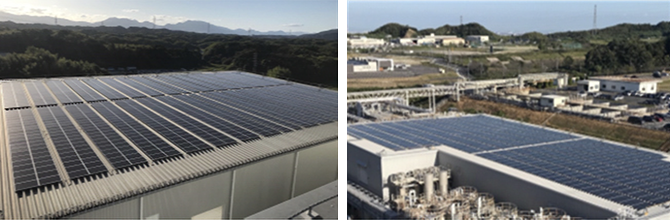

Efforts to Improve the Ratio of Renewable Energy

USJC will increase the ratio of renewable energy such as solar power among the electricity used in our plant with the aim of contributing to a decarbonized society.

In 2023, solar panels at Mie Plant generated 992 MWh of electricity. We will continue to systematically install solar panels on our site.

Solar power panel installed in Mie Plant

![]()

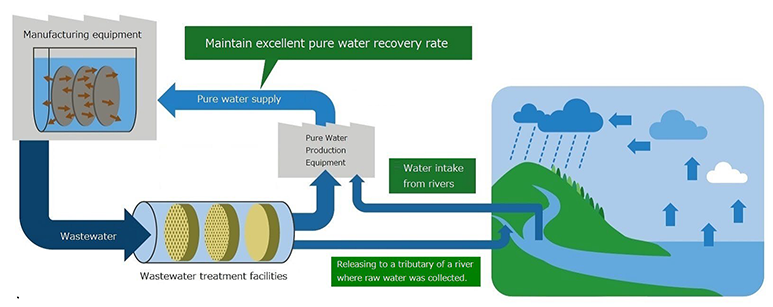

Water Resources Cycle

On production lines, USJC works to conserve water resources by recovering process effluent after pure water use, and recycling effluent into pure water again.

Acid-alkaline and hydrofluoric acid effluent are collected, recycled, and reused to replenish circulating water in exhaust-gas treatment equipment, as washing water, and so on. We are working to realize water resources cycle by returning clean water, properly treated with water treatment systems based on the latest technology, to the rivers joining main rivers from which industrial water is drawn. We will actively strive to improve its water recycling rate and achieve even more effective use of water resources.

Overview of water resources cycle

![]()

Reduce Industrial Waste Generation

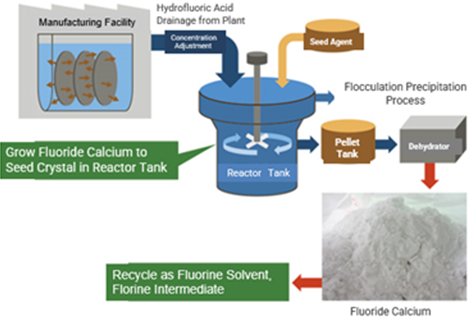

USJC actively implements 3R (Reduce, Reuse, and Recycle) to reduce environmental burden. We have also installed stirred type crystallizers developed for high concentration fluorine-containing effluent treatment and formed particulate fluorite from recovered high concentration hydrofluoric acid effluent. Through installation of such equipment and sales to chemical manufacturing companies, the company has achieved a mechanism for sourcing recycled hydrofluoric acid. We are also working on the effective use of resources by collecting waste sulfuric acid used at plants and selling it for reuse in wastewater treatment. Additionally, separating the collected waste oil and waste solvents in a proper way, implementing reusing renewable fuels as raw materials and using fuel sources in place of fossil fuels will be expected to contribute to the establishment of a Sound Material-Cycle Society. Through these efforts, the amount of waste generated in 2023 was reduced by approximately 1,537 tons compared to 2019.

Fluorine Recovery and Recycle System

USJC has introduced a "stirring crystallizer" developed for the treatment of highly concentrated fluorine-containing wastewater. It produces particulate fluorite from the recovered highly concentrated fluorine acid wastewater, which is then sold to a chemical agent manufacturing company to be recycled again as a raw material for fluorine acid production.

![]()

Collaboration in Environmental Activities

with suppliers

USJC is required collaboration in environmental activities with suppliers by the recent global movement to reduce environmental impact and the needs of external stakeholders.

Since 2018, we have asked onsite gas suppliers with favorable regional conditions and close relationships cultivated over many years to cooperate with us and have exchanged opinions and started initiatives on three specific collaborative perspectives: 1) CO2 emissions reduction, 2) Biodiversity conservation, and 3) Water resource conservation.

![]()

![]()

![]()